Tech

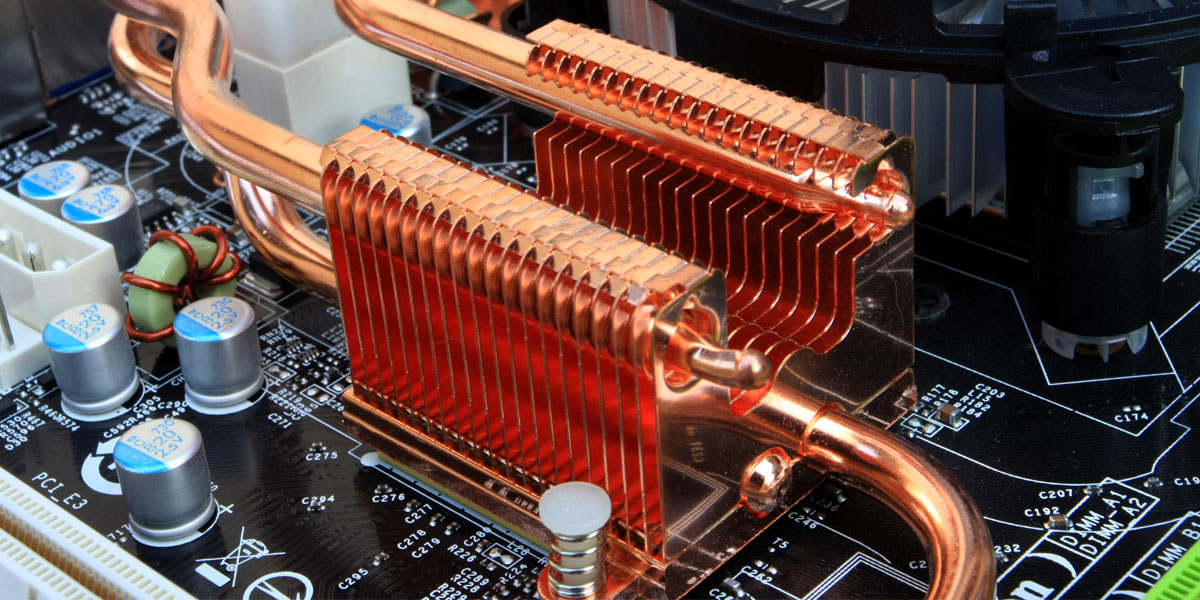

Understanding Heat Sinks: How do Heat Pipes Work

In electronics, it’s important to control heat so devices don’t get too hot and stop working properly. Heat sinks, especially heat pipes, help by moving heat away from hot parts, keeping things cool. These smart parts are used in devices like gaming consoles and laptops to prevent overheating. In this post, we’ll explain how do heat pipes work and how heat pipes help remove heat from important components. You’ll see how they help keep your devices cool and running smoothly!

Table of Contents

What Is a Heat Pipe?

A heat pipe is a sealed tube that moves heat efficiently without using any electricity or moving parts. It does this by using a special liquid inside that evaporates (turns into vapor) when heated, carrying heat from the hot side to the cool side. Then, the vapor cools down and condenses into liquid, releasing the heat. The liquid then flows back to the hot side to repeat the process, usually helped by a wick inside or gravity.

This cycle moves heat quickly and smoothly with very little temperature difference.

Common Uses

Heat pipes are used in many fields because they cool things efficiently and quietly:

- Consumer Electronics: Heat pipes keep processors and graphics cards in laptops, smartphones, gaming consoles, and LED lights cool without making noise from fans.

- Data Centers & Servers: They help remove heat from powerful computer parts so systems don’t overheat and can run smoothly.

- Aerospace & Satellites: Heat pipes help keep space equipment at steady temperatures by moving heat to radiators, even in zero gravity.

- Automotive Industry: Especially in electric cars, heat pipes cool power electronics to keep them safe and working well.

- HVAC Systems: Heat pipes improve HVAC systems by recovering energy and controlling moisture efficiently.

Basic Structure of a Heat Pipe

- Outer Shell (Enclosure)

This is the sealed metal tube that holds everything inside. It’s made from metals that conduct heat well, such as:

- Copper: Great for electronics cooling because it transfers heat very efficiently.

- Aluminum: Lighter than copper, often used in aerospace and cars.

- Stainless Steel: Used when things get very hot or corrosive conditions exist.

The enclosure keeps a vacuum inside, which helps the working fluid evaporate and condense easily.

- Working Fluid

This is the special liquid inside that moves heat by evaporating and condensing. Common fluids include:

- Water: Most common, works well up to about 200°C.

- Ammonia: Used for higher temperatures, like in spacecraft.

- Acetone: Good for low-temperature uses.

- Refrigerants (like R134a): Used in air conditioning and electronics cooling.

The choice depends on the temperature range and what the heat pipe is cooling.

- Wick Structure

The wick lining inside the tube helps pull the liquid back to the hot area after it cools and turns back into liquid, allowing the heat pipe to keep working efficiently. Types of wicks include:

- Sintered Powder Wick: Made of metal powder, very good at moving liquid back, used in high-power devices.

- Grooved Wick: Has grooves inside the pipe; cheaper but needs to be oriented correctly to work well.

- Mesh Wick: Made of metal mesh layers, flexible, and performs well.

The wick type affects how well the heat pipe works and whether it needs to be positioned a certain way.

- Vacuum Inside

The heat pipe is kept under a vacuum (low pressure) inside.

This vacuum lets the working fluid evaporate at lower temperatures, which helps the heat pipe transfer heat efficiently.

How Do Heat Pipes Work?

- Evaporation (Heat Absorption)

The heat from a hot part (like a CPU) heats the fluid inside the heat pipe, causing it to evaporate and carry heat away as vapor.

- Vapor Transport

Hot vapor moves through the pipe’s hollow center to the cooler end, driven by pressure differences, carrying heat efficiently.

- Condensation (Heat Release)

Vapor cools and turns back into liquid at the cooler end, releasing heat to a heatsink or cooling surface.

- Return via Capillary Action

The liquid returns to the hot end through a wick inside the pipe, which draws it back like a sponge to keep the heat transfer going.

Passive Operation

- No Moving Parts: Heat pipes don’t use fans or pumps , they rely on the natural movement of the fluid inside.

- No External Power Needed: They work without electricity, making them energy-efficient and reliable.

- Self-Sustaining Cycle: As long as there’s a temperature difference between the hot and cool ends, the cycle keeps going automatically.

This simple but powerful process allows heat pipes to move heat quickly and quietly, making them perfect for cooling electronics, spacecraft, air conditioners, and more.

Key Advantages of Heat Pipes

- High Thermal Efficiency

Heat pipes transfer heat extremely well, often hundreds of times better than solid metals like copper or aluminum. They do this by using a special process where a liquid inside the pipe evaporates (turns into vapor) when heated and then condenses back into liquid when cooled, moving heat quickly over long distances. This makes them perfect for cooling things like high-power electronics and aerospace equipment that produce a lot of heat.

- Compact and Lightweight

Even though they cool very effectively, heat pipes are small and light. Their clever design lets them fit into tight spaces without adding much bulk or weight. That’s why you find them in portable gadgets like laptops, smartphones, and tablets.

- Quiet and Reliable

Heat pipes work quietly and are reliable since they have no moving parts, making them ideal for quiet environments like medical devices and high-end computers.

- Used in Many Industries

Heat pipes are useful in lots of fields because they are so versatile:

- Consumer Electronics: Cooling laptops, phones, and gaming consoles.

- Aerospace & Spacecraft: Controlling temperatures in satellites and space vehicles where normal cooling doesn’t work well.

- Renewable Energy: Helping solar panels and geothermal systems transfer heat better to capture more energy.

- HVAC Systems: Improving energy efficiency by moving heat between incoming and outgoing air in ventilation.

Heat pipes offer strong, quiet cooling in a small space, making them vital for efficient heat management across many industries.

Factors That Affect Heat Pipe Performance

1. Working Fluid Choice

The type of liquid inside the heat pipe is important. It decides the temperature range the heat pipe can work in and how well it transfers heat. The best fluids conduct heat well, flow easily, and evaporate at the right pressure. For example, water is great for temperatures up to about 200°C. For higher temperatures, fluids like ammonia or acetone work better. Also, the fluid must be compatible with the materials inside the pipe to avoid corrosion and keep the heat pipe working for a long time.

2. Wick Design and Material

The wick inside a heat pipe acts like a sponge, pulling liquid back to the hot area where it evaporates. It uses capillary action, which means it moves liquid through tiny spaces. Different wick designs and materials are chosen based on what the heat pipe needs to do.

3. Pipe Material and Diameter

What the pipe is made of affects how well it conducts heat and how strong it is. Copper is often used because it conducts heat well, but aluminum is lighter and sometimes better for specific uses. The pipe’s diameter (thickness) also matters: bigger pipes can handle more heat, but they may need more complex wicks to keep the liquid moving properly inside.

4. Orientation and Installation

Heat pipes can usually work in many positions, but some angles affect how well they perform. If the evaporator (the hot part) is above the condenser (the cool part), gravity helps the liquid flow back. If it’s the other way around, the wick has to work harder to pull the liquid against gravity. If the wick can’t do this well enough, the pipe can dry out and lose efficiency.

For a heat pipe to work efficiently and last, choose the right liquid, wick, materials, size, and install it correctly.

-

Health5 years ago

Health5 years agoAdvantages and Disadvantages of Milk

-

Tech4 years ago

Tech4 years ago6 Tips to Improving E-Commerce Websites

-

Home5 years ago

Home5 years agoAdvantages and Disadvantages of Village Life in Points

-

Travel5 years ago

Travel5 years agoAdvantages and Disadvantage of Travelling

-

Sports4 years ago

Sports4 years agoThe benefits of playing an online live casino

-

Tech5 years ago

Tech5 years ago10+ Advantages and Disadvantages of Mobile Phones in Points

-

Tech5 years ago

Tech5 years agoEssay on Advantages and Disadvantages of Offline Shopping

-

Tech5 years ago

Tech5 years ago8+ Advantages and Disadvantages of Motorcycle |Having Bike